Enamel sterling silver box Salimbeni Value: discover the secrets of manufacturing process.

A Salimbeni enamel sterling silver box is a concentration of craftsmanship, artistic expression and exclusivity.

To understand its properties you need to go beyond the image for other amazing things and go deep into a depth that not all objects can have.

Obviously this can be said for all Salimbeni products.

Table of Contents

The Salimbeni enamel sterling silver box are real creations of craftsmanship of the highest level.

Find out how many skills are needed to make a Salimbeni enameled product.

How to build a Salimbeni enamel sterling silver box.

The construction of a silver box, even if it has a very simple shape, is always particularly complex, especially if incisions, carvings, guillochés and fired enameling are to be carried out.

A sterling silver sheet is the first step in building a Salimbeni enamel sterling silver box.

The sterling silver sheet are commercially available in various thicknesses. These are the precious metal benches that melt the silver to the required fineness (e.g. 925 for sterling silver). They supply semi-finished products that arise from silver castings which are then laminated. Normally the slabs have standard dimensions of cm. 50×150.

The thickness we use for the boxes, but also for the other objects that will have to be fire enamelled, varies from a minimum of 10/10 to 15/10 (of a millimetre).

The development of the design on the slab to build a Salimbeni enamel sterling silver box.

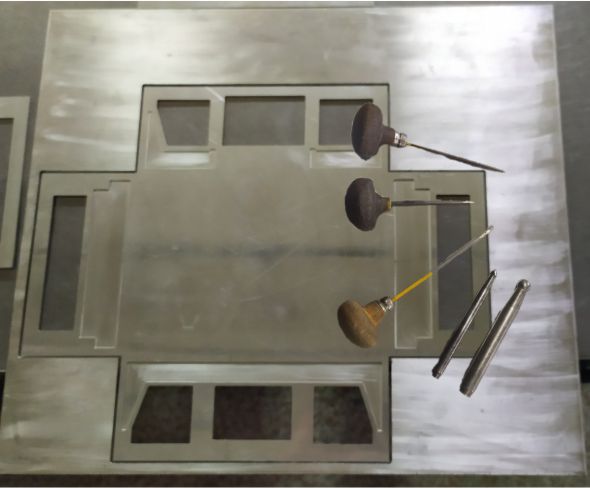

Like a tailor draws the model on the fabric before cutting it, so the slabs are cut to size with cutters or pantographs. Along the sides that will have to be folded, we work with “burins” to obtain perfectly acute and square angles or with other tricks for rounding, cambering or curves.

The welds needed to build a Salimbeni enamel sterling silver box.

The Precious Metals Act stipulates that solders for silver must always also contain silver in the alloy. Therefore, “tin-plating” or other non-precious metal alloys are prohibited.

The sides that match are welded. In the case of working with enamels, they must be very resistant to withstand the high temperatures to which they will subsequently be subjected.

They will therefore also be reinforced on the edges with silver “squares”,

Important details of building a Salimbeni enamel sterling silver box.

To create a “lost hinge”, i.e. semi-invisible, hinges of a larger diameter and thicker are created so that they can be filed evenly with the slab of the side of the box.

For spherical or cylindrical boxes we make use of workings of the plates with lathes or forgings. They are compressed with suitable “stozzi” in polyurethane rubber with hydraulic presses.

This helps shape the object, but the perfect adjustment must always be done manually.

When the box is completed with the addition of snaps, nails, etc., it is cleaned and cleaned.

The decoration phase is very important for building a Salimbeni enamel sterling silver box.

Finally we move on to the design phase. In this step it is necessary not only to sketch the decorative motif but to carefully calculate the spaces as the surfaces to be glazed must be surrounded by a slightly oblique step, capable of containing the liquefied glaze

Hand engraved

To do this, all the contours are drawn with a burin, with the aid of compasses and steel sticks, the sketch of the design is manually excavated for about 3.5/10 where the enamel will be deposited. Finally, always by hand, the fields to be glazed are completely engraved with their borders.

It should be taken into account that each color has its own defined space and firing, it is difficult to fire several colors together.

Guilloche engraving

Also in this case all the contours are drawn with a burin, which are then dug with the guilloche machines which are dug both with the guillochè and manually for about 3.5/10 all the seats where the enamel will be deposited. Finally always with the guilloche, but also manually, the fields where the enamel will be deposited are engraved.

Hand engraving + Guilloche engraving

When the unsurpassed hand of the engraver superimposes a particular engraving on the “guilloché”, a myriad of different designs intertwine which, in addition to the color, create chiaroscuro effects of great effect under the transparent enamel. Of particular beauty are the hand engravings that reproduce motifs with elements, landscapes, architectures, paintings by Renaissance authors.

Glazing or enameling

It is obtained by depositing the crystal powder which melts with heat and vitrifies with the final cooling. The technique we use is “champlevé”, or incision (or hollow alveoli).

Glazing with Miniatures

The enamelled miniatures follow a particular construction process for which still different and profound skills are required. When it comes to painting a subject on the enamel and then firing it, things get very complicated.

We always start with an incision of the area where we will then go to paint the miniature which has the purpose of creating the containing edges of the enamel. Milky white enamel will be placed in it which will act as a virgin canvas for the painter. The drawing will not be made all at once but color by color and fired every time with numerous exposures to temperatures around 700° < 800° C.

At the end of the painting, the whole area is subjected to a new coat of enamel, this time transparent, to protect the whole.

A beautiful miniature varies from 20 to 50 firings.

Enamel with Paillons in 24 carat gold.

It is the insertion between the different layers of enamel of gold motifs called Paillons with a thickness of a few hundredths of a millimeter, which can be leaves, flowers, stars, motifs of various kinds, but always very small, generally on a bottom of a dark color, and subsequently covered with a transparent layer.

The galvanic bath : to finish building a Salimbeni box

After all these operations the box, the object is ready for the galvanic bath with which a layer of 24 carat gold is placed on the parts not covered by the enamel. This procedure takes place with normal galvanic baths but with times and methods expressly calibrated on these objects.

These work of art are always unique pieces, no one is ever the same as another.

This statement needs no explanation. It is clear that building the pieces entirely one at a time it is impossible to find 2 equal.

Even in the (rare) cases of multiple copies we can say that each of them is an original copy

Salimbeni have created products for many luxury brands, in which their 391 Fi Mark can be found next to the brand signature

Our 391 FI brand is present on all our products.

In the case of products made for brands, it is found together with their brand and silver fineness (925).

All the producers of objects in precious metal are registered in particular lists kept at the chamber of commerce of the area where they reside.

These identifiers once assigned can no longer be reused for other manufacturers so that it is absolutely certain who built that particular object

Many thanks for Your interesting, click on Button to visit Salimbeni Boxes Gallery or fill the form to enquiry Us.

Fill the form to contact Us and/or to receive Our offers.